Vision

Compliance to code and international standards is assured through MWI’s ISO 9001:2015 accredited Quality Management System. The organization is acutely focused on end-user satisfaction, continuous improvement, and managing projects from design through system start-up.

The company, through its newly formed CRDX brand is strategically positioned to support the Energy Transition leveraging the decades of subject matter expertise around the use of hydrogen. As part of our commitment in supporting our customers through this transition to carbon free energy, we take a full spectrum view of carbon reduction strategies across the range of fuels available to power producers today – and to those being developed for the future.

We maintain a view that celebrates the gains made by operators of today’s installed base of plant & equipment, fully recognizing the indispensable role natural gas, nuclear, and renewables play in the quest for a carbon-reduced environment.

Met Weld International has decades of experience in support of Energy.

Met Weld was formed around the core competencies of welding and fabrication. This remains a central element of the business, exemplified by certificates of authorization for ASME Section III, Section VIII, and demonstrated compliance to the European Pressure Equipment Directive (PED) and NavSea.

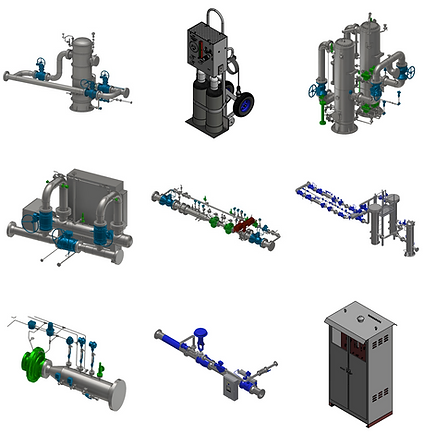

MWI adds decades of subject matter expertise across turbine-generator applications and system integration to that foundation -- from liquid/natural gas fuel conditioning systems for large steam and gas turbines – to critical auxiliary systems and condition monitoring for large hydrogen-cooled generators.

Full Spectrum Solutions

“a full spectrum view of carbon reduction across a range of fuels"

The Met Weld’s perspective begins with liquid and natural gas fuel conditioning systems, where optimizing pressure, flow, and temperature – combined with removing impurities and other fuel contaminants -- helps lead to more efficient turbine operation.

Met Weld’s legacy systems within this segment number in the thousands, worldwide. And we are carrying that contribution forward – in our development and supply of green hydrogen-blending systems through our CRDX brand that further reduce carbon utilization, while simultaneously increasing the use of renewable energy.

Focus on Carbon Utilization

Met Weld brings perspective, and experience, across application engineering, component supply, fabrication, system integration, controls, and field support. We look forward to meeting with you.

Added efficiency and lower carbon utilization moves from the turbine to the generator environment – where seal oil, gas cooling, and gas condition monitoring systems support safety, reduced windage loss, and optimum heat absorption & transfer. Hundreds of Met Weld critical auxiliary systems provide support to operators of hydrogen-cooled generators in this part of the power train, worldwide.

“further reduce carbon utilization, while simultaneously increasing the use of renewable energy."

“Increased Turbine/Generator Efficiency

= Lower Carbon Utilization per MW”

Capabilities

Contact us for a presentation of capabilities:

Met Weld’s integrated solutions support the goal of reducing carbon emissions through increased efficiencies and the introduction of carbon free fuels.

Learn more about:

-

Specific products and technologies

-

How products and technologies integrate

-

Met Weld manufacturing strength and capabilities

Capabilities

-

Application Engineering

-

Quality and Safety

-

Organization and Facilities

Products

Met Weld’s integrated product solutions support the goal of zero emissions

Our Leadership Team

Morgan Connor

President

Since 2005, Morgan has played a key role in the overall strategy for Gavial Holdings and its’ family of companies. He currently serves as President of Gavial Holdings and Met Weld since 2012, and as President of MWI, Morgan is well positioned to lead MWI in the development of carbon reduction technologies and infrastructure.

Ron Brosnihan

VP and Business Unit Leader

Ron joined Met Weld in 2017 as the organization’s business unit leader. He has 25 years of experience in power generation, most of which has been spent in leadership roles. Ron has a background in market development, operations management and product development. His focus has been aligning Met Weld and CRDX’s capabilities to the needs of turbine/generator OEM’s and power producers.

Gus Graham

Business Development Manager

Gus brings 25 plus years of power generation experience spanning R&D, Engineering Management and Business Development in clean coal technology, hydrogen fuel cell system and hydrogen cooled generator auxiliary systems. Gus joined MWI as the Business Development Manager in 2022 to leverage his technical and commercial competencies and grow the MWI footprint both domestically and internationally.

Steve Kilmartin

Principal Technical Advisor

Steve brings forty plus years of experience as a Utility Products Specialist focusing primarily on power generation with emphasis on hydrogen cooled generator auxiliary systems. Steve joined Met Weld in 2019 as the Principal Technical Advisor for generator auxiliary systems and is also the Principal Technical Advisor for CRDX.

Dan Hill

Lead Technical Advisor/Mechanical Engineer

Dan brings thirty plus years of experience focusing primarily on liquid and gas process systems integration with emphasis on power generation applications.